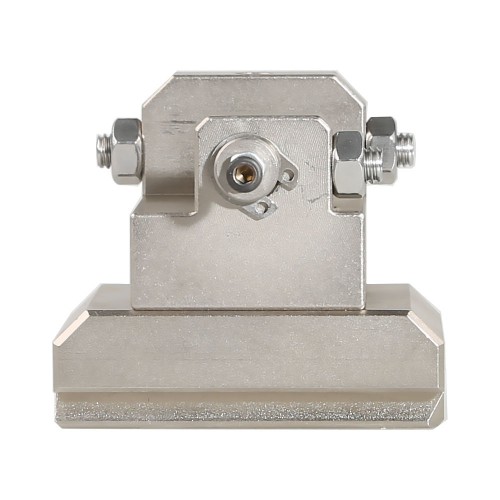

Product Description

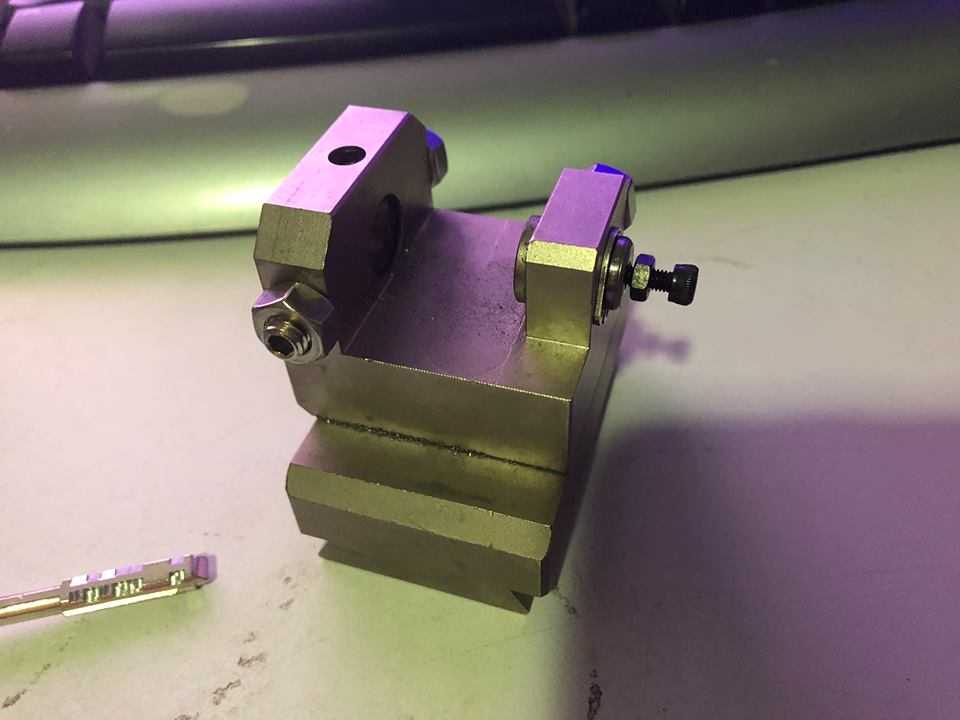

Xhorse M3 Fixture for Ford TIBBE Key Blade Works with CONDOR XC-MINI Master Series/ Dolphin XP005/ Dolphin XP007 etc..

Xhorse Ford M3 Fixture for Ford TIBBE Key Blade

Function:

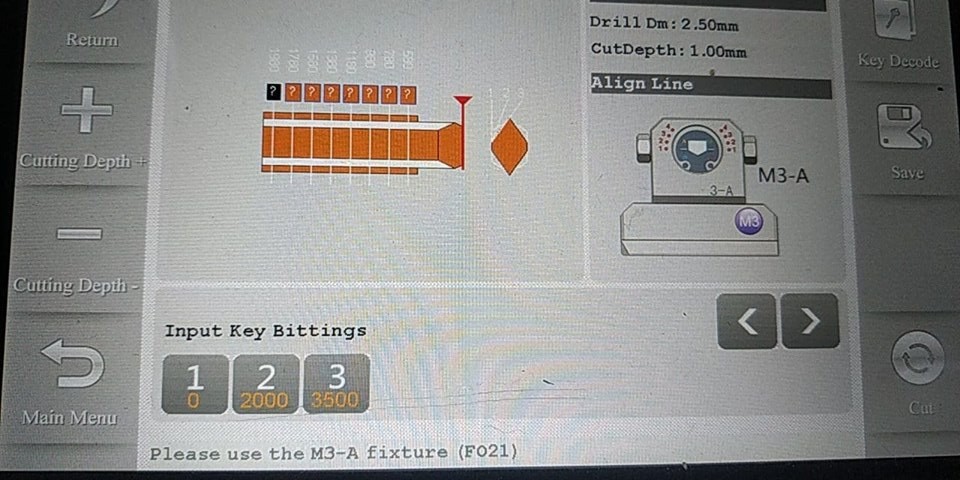

Works withCONDOR XC-MINI Master Series/ Dolphin XP005/ Dolphin XP007 etc Key cutting machine

Packing lists:

1pc x Ford M3 Fixture

Shipping Method and Delivery Time:

EU, UK , US and Russia Warehouse Shipping: 3-5 working days. Fast Delivery & Tax Free.

China Warehouse Shipping:

DHL Shipping: 3-5 working days. Usually we declare a lower value on DHL invoice to help with customs clearance. Please remember to leave message if you have any special requirement.

Yanwen Express: 7-10 working days. No Tax for European Countries.

Standard Post: 7-15 working days. To South America and Africa countries it may take 20-25 working days. Customers can tick Express Shipping Service to ship by DHL.

For any question, please contact us at:

Tech Service

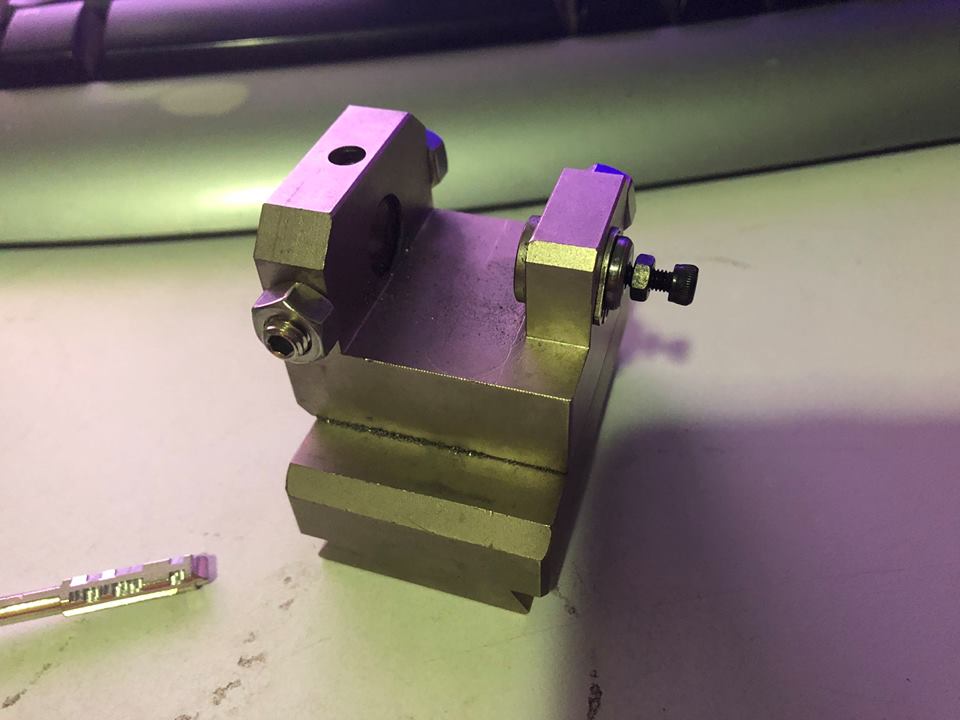

Here are some tips of using the tibbe jaw (M3-A) from customer feeback

Credit for Victor Dust

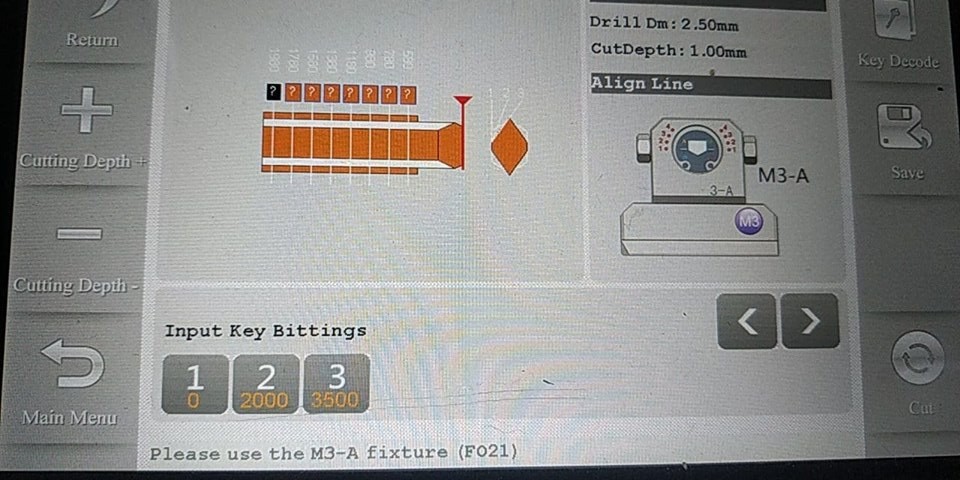

It’s aimed to cut a Jaguar 8 cut key with a Condor Mini machine

Have just cut the key and it seems to be 1 cut in front / 1 cut behind in placement.

Q: How far should this screw be in / how far out should it be??

A: tbe1

Q: How much does the rear screw need to stick out?

A: It is necessary to re-adjust the position of the key in the vice.

Q: what the best way to make sure it lines up in the correct place perfectly.

A: With the correct attitude, the machine itself will go to the right distance to puncture the key into the position of the first secret. at Ford it is shorter.

Q: I will give it another go fingers crossed lol

A: if properly configured for the Ford device, then do not re-adjust the vise of the length of the bolt. stand the workpiece of the key and cut it

Q: how far out do you have your screw?

A: in the vice, the key is the Ford, and the milling cutter has entered the required length independently. Do not be afraid

Q: the last cut i did was wrong it was to far forward by nearly a complete cut

A: It is necessary to adjust when the milling cutter stands in such position as at me on a photo. remove the vice and adjust the depth of the key with the screw, each time looking closely at how the milling cutter is positioned. The cutter must be in the position of the first secret

you do not have a vise

as you adjust the screw, tighten the fixing nut so that the screw does not hang and unwind. I'm sorry, I've got to go to the client.

try to insert the key deeper. with effort.